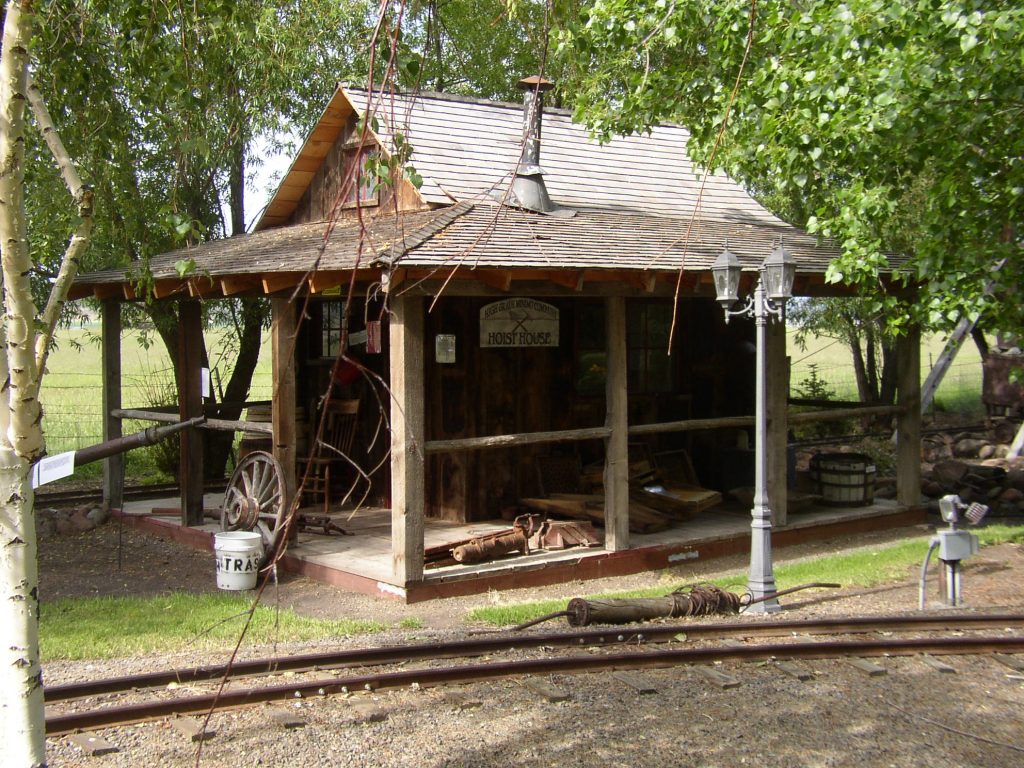

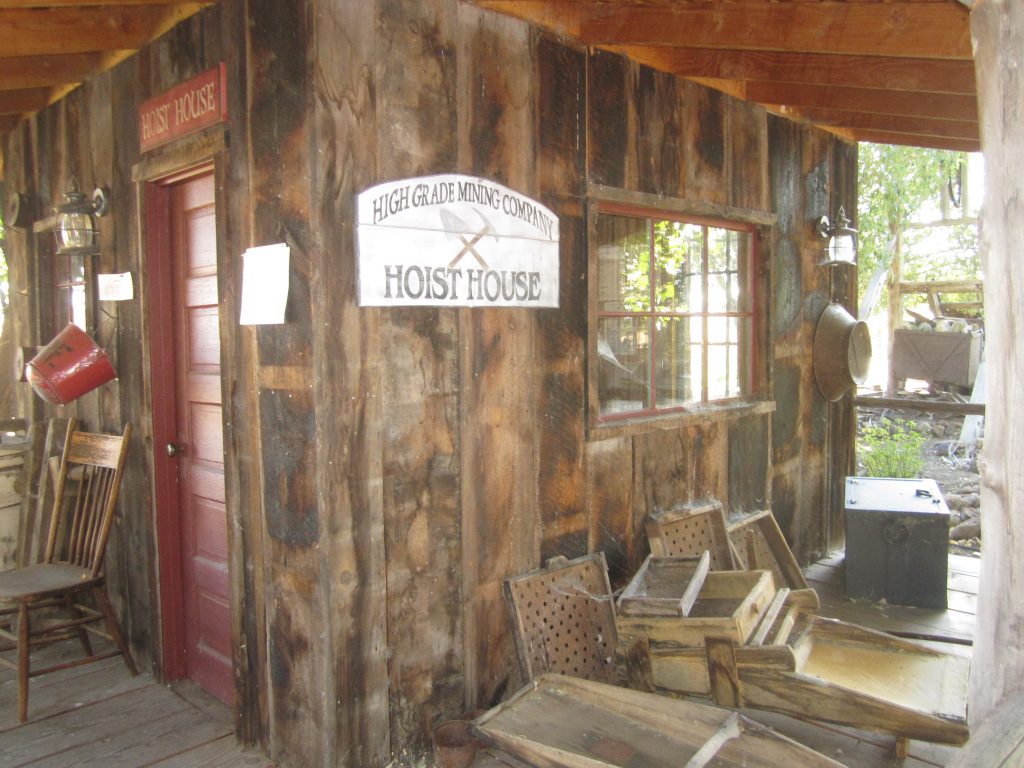

HIGH GRADE MINING COMPANY HOIST HOUSE

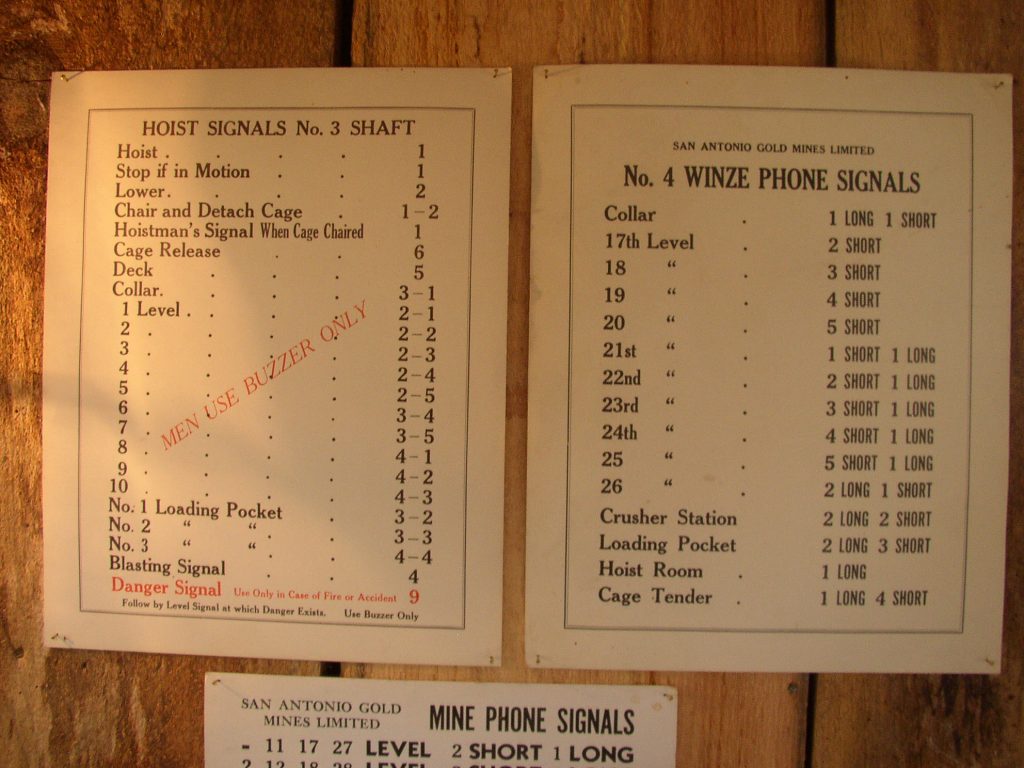

During the gold rush, when the easy surface gold (placer gold) ran out, hard rock mining was developed to follow the gold veins deep into the earth. The Hoist House at a gold mine housed the machinery that transported men deep into the mines, and pulled the ore cars and skips laden with gold-bearing ore to the surface for processing. The cable going through the wall from the hoist went over a headframe wheel and then attached to an ore skip. The hoist operator knew when to stop and start the hoist based on a series of bell signals from workers deep in the mine.

The hoist operator was one of the most trusted, experienced, and respected workers in a mining operation. The lives of his fellow miners were in his hands. Using only a system of bells, he could stop and start the ore cars at any level in the mine shaft—sometimes over a mile below the surface.

In 1949 Stephen lived in the old French Hotel in Cedarville, CA, with his three brothers, sister and mother. The siblings always played in the smoke house in the back of the hotel which can be seen sticking out from behind the hotel in the photo above. Pictured on the right are Stephen and his sister Chris on the porch of the French Hotel. Years later, Bill Reeves dismantled the smoke house and stored the lumber at his house in Lake City. In 2006 Bill gave the lumber to Stephen. This Hoist House is built from the smoke house lumber, with the smokey interior wood facing out. If you look at the outside walls of the Hoist House, on the porch by the gold cradles, you can see the large rough lumber mill saw marks on the lumber, as well as the black smoke imbedded in the wood.

In the photo on the right, our sons Joshua and Will, as well as our granddaughter Clare, visit the Hoist House.

Hydraulic monitors, commonly referred to as “Giants”, were huge water nozzles that were used to direct enormous quantities of water in a concentrated stream against a hillside. The water would move mountains of overburden to get to the gold carrying pay dirt near bedrock. Monitors were outlawed in California in 1884 because the silt choked the region’s waterways.

To operate the monitors, water was transported to the mining site in flumes and then channeled into riveted pipes. The pipe leading to the monitor would be gradually decreased in size, thereby increasing the water pressure. A large monitor could easily shoot a stream of water 100 yards. The stream of water was so powerful that it could blow a man into the air at 50 yards, killing him.

A gold rocker was the first “mechanized” improvement over panning for gold and silver. The gold bearing soil was shoveled in the top tray, and a steady stream of water was introduced. The prospector rocked the cradle to facilitate the separation of the heavier gold and silver from the dirt and gravel. The gold and silver settled in the riffles while the water carried the lighter dirt and gravel away. The process was completed when the prospector scrapped the residual gold and silver from the riffles in the lower tray. If it was available, mercury would be put in the riffles because gold and silver adhere to pure mercury. The mercury would later be cooked off and reclaimed.

Fire buckets, like the one pictured above, were hung on a wall near barrels of water in the old time saw mills and mining camps. The buckets were manufactured with round bottoms to make them worthless for other uses so the workers wouldn’t steal them for personal use (they tip over when placed on the floor).

The earliest pipes used in mining towns were made of Douglas Fir or Redwood and wrapped with wire. Iron was in short supply during the gold rush, and that is why this style of pipe was built. To join two sections of pipe, the tapered end of one was inserted into the wide end of another. When water was introduced into the pipe, the wood would swell, sealing the pipe. The wire wrapped wood pipes were so strong they were used to deliver water under pressure to hydraulic monitors when metal pipes were not available.

This pipe was made in San Francisco by the Pacific Pipe Company. Some pipes like these are still in use in Virginia City, NV, where they were installed as underground water pipes in the 1800s.

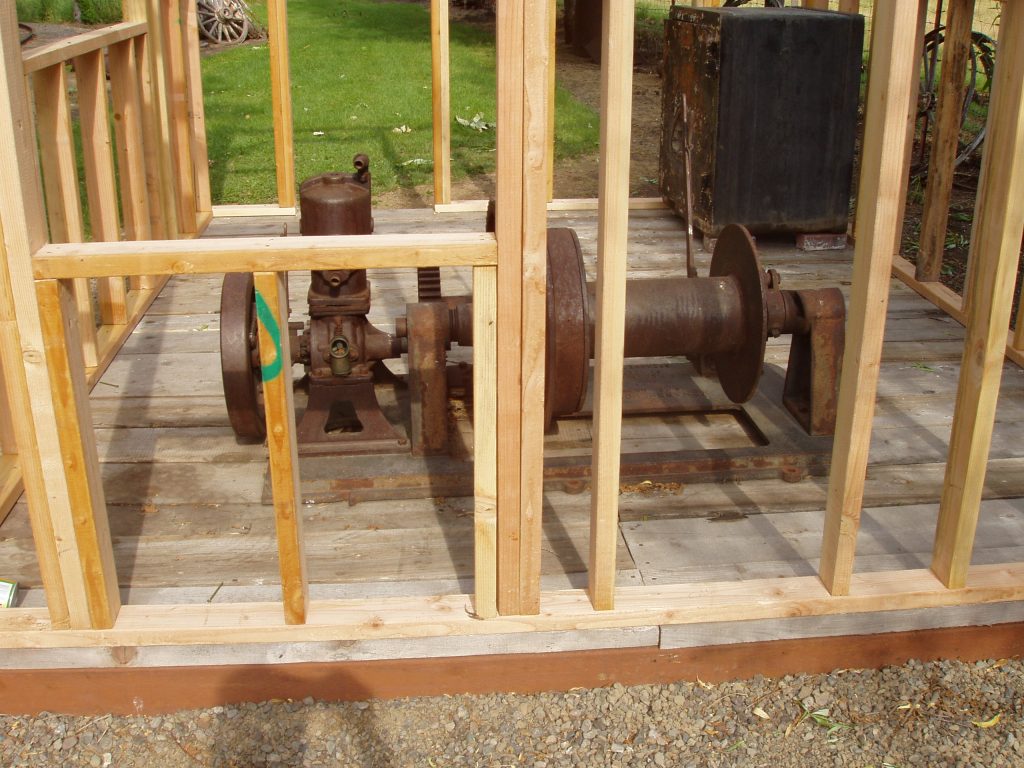

The hoist in our Hoist House was operated by steam and built in 1888. The steam hoist is so heavy that it had to be placed on the floor of the building, and Stephen then built the building around the hoist.